ENGINEERING TECHNOLOGIES

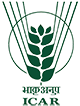

Hand-operated chipping machine

Hand operated chipping machine consists of two concentric mild steel drums, the annular space between which is divided into compartments for feeding the tubers, supported on four MS legs. A rotating disc at the bottom of the drum carries the knives assembly. A pair of HSS bevel gears is provided to operate the machine manually with a crank arm. Tubers are fed into the compartments from the top and the chips are collected at the bottom .Capital cost of the machine is approximately Rs 17850/-.

Pedal operated chipping machine

The pedal operated chipping machine is the modified version of the hand operated prototype with additional provision of a pivoted pedal for transmitting the power to the cutting disc through suitable belt and pulley drive mechanism. A trimming knife is also provided on the frame to remove the woody neck portion of the tubers before feeding into the compartments. Four castor wheels are fixed to the legs of the machine to make it portable. Cost is approximately Rs 25000/-.

Motorized chipping machine

The motorized chipper developed is run with a 0.5 HP single phase motor through suitable belt drive. The feed hopper consists of two concentric rows of 25 cm high ms cylinders. The outer row of cylinders is of 10 cm diameter while the inner row of cylinders meant for thinner tubers are of 7 cm diameter. A MS circular disc of 87 cm diameter and 10 mm thickness carries two pairs of stainless steel blades.

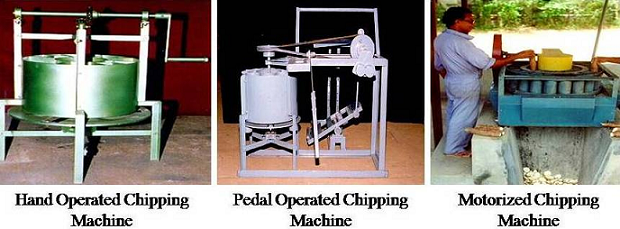

The mobile starch extraction plant is cost effective equipment permitting on-farm starch extraction by the producers and thus avoids the exploitation of the farmers by middlemen.

The major components of the machine are hopper to feed the tubers, crushing disc or cylinder with nail punched protrusions rotating inside crushing chamber to crush the tubers, sieving tray to remove the fibrous and other cellulosic materials, stainless steel or plastic tanks to collect the sieved starch suspension, tuber storage chamber, handle and wheels for easy transportation from place to place and a frame to support these components. An electric motor (¾ HP) or a generator (kerosene–petrol) attached to the frame can be used as the energy source to operate the machine. The size of the equipment is 1350 x 1800 x 1320 mm and the capacity of the machine is 120-200 kg h-1.

Features

• Suitable for starch extraction from different tuber crops

• Provision for easy transportation

• Provision to store peeled tubers

• Provision for easy removal of rasper blades

• Easy to fabricate, operate and maintain

The rasper consists of a crushing drum made up of a mild steel pipe with power hacksaw blades fixed on its circumference. The crushing drum is fixed on a shaft, power to which is provided by anelectric motor with belt and pulley. The drum is rotated inside the crushing chamber which is made up of two halves, the upper being act as hopper and the bottom half portion acts as outlet for the crushed mash to flow. Gap between the blade set and crushing chamber is adjusted to minimum. A changeable sieve plate is provided in the bottom half to filter the starch pulp with out any bigger pieces. Capacity machine ranged from 800 to 1000 kg h-1.

Two level type harvesting tools have been developed in CTCRI. Only 14-15 mandays are required to harvest one hectare of cassava whereas 30-34 mandays are necessary for manual operation. These low cost mechanical devices reduce the drudgery involved with the manual harvesting. a. First order lever type: The lever is supported on a fulcrum, which in turn is supported at the top of a stand. During the operation, the jaws open just enough to get around the cassava stem. It has a mechanical advantage of four and its weight is 14 Kg. It costs approximately Rs.2500/- b. Second order lever type: The height of the fulcrum at the far end of the lever can be adjusted which facilitates uprooting of cassava plants raised on flat bed as well as on mounds or ridges. A self tightening mechanism is used to grip the cassava stem. It has a mechanical advantage of 3.4 and the total weight is 8 Kg. It costs approximately Rs. 1800/-.

Sweet potato (Ipomoea batatas Lam.) is cultivated throughout the tropics and warm temperate regions of the world for its starchy roots, which can provide nutrition, besides energy. A number of novel food products with functional value are being developed worldwide. Sweet potato tubers with their low glycaemic index have additional value as a food for diabetics. There are a range of primary food products that could be made from sweet potato like chips, flakes, frozen products, French fries, puree etc., while it is also the raw materials for a host of secondary products like noodles, sugar syrups, alcohol, pasta etc.

Sweet potato based composite flours have been used in many countries for making small baked goods like cakes, cookies, biscuits, doughnuts etc. Sweet potatoes are consumed at home level, mainly after cooking, baking or converting into fried chips. The roots are often converted to canned or pureed form, to enhance the shelf life. Sweet potato based baby foods are preferred in many countries as the first solid food for infants. Canning of sweet potato is widely practised in the United States, to enhance the storage life and ensure round- the year availability of the product.

Sweet potato roots are transformed into more stable edible products like fried chips, crisps, French fries etc. Sweet potato puree, is a primary processed product from the roots, which is used directly as a baby food or used for mixing various food items like patties, flakes, reconstituted chips etc. High quality puree can be made from white, cream or orange- fleshed sweet potatoes and also from tubers of any size or shape.

Sweet potato has assumed great significance in recent years as a health food due to the various bioactive principles in it. It was found that high protein/fibre pasta could be made from sweet potato using protein sources like whey protein concentrate or defatted soy flour pr fibre sources like wheat bran or oat bran. Use of orange fleshed sweet potato variety, Sree Kanaka resulted in a dark orange coloured pasta which had low starch digestibility and high resistant starch content, besides high carotene content.

Sweet potato roots can be termed as a ‘3-in-1’ product, as it integrates the qualities of cereals (high starch), fruits (high content of vitamins, pectins etc.) and vegetables (high content of vitamins, minerals etc.). The beneficial effects of these ingredients have been appropriately put to use by converting the roots into a number of intermediary food products like jam, jelly, soft drinks, pickles, sauce, candies etc..

The tuber crops snack foods were produced by extrusion cooking to develop direct expanded extradites.

Features

• At present no cassava extruded products are available in the market.

• Extrusion of cassava gives a high expanded product with a bland taste. Cassava extrudates are totally oil free and hence has much dietetic value.

• Cassava flour is a cheap raw material at the cassava growing belts.

The baked food products play a crucial role in Indian diet as they are partially substituting meals in the breakfast and dinners. Major product categories include biscuits, cookies, snacks, cakes, pastries and rusks and puffs, while few new product types like cupcakes, strudels, waffles and doughnuts are also added in the recent days.Gluten is a mixture of proteins found in wheat and related grains, which gives elasticity to dough and gives “spongy” texture to baked foods like pasta, bread, cookies, pizzas, etc. Despite improving the texture of baked goods, gluten is considered as a harmful ingredient as it interferes with the absorption of nutrients, and its consumption leads to Celiac disease. The current prevalence of Celiac disease in India is estimated as 1% and commonly found in north India where wheat is a staple food. A lifelong gluten free diet (maximum of 20 mg of gluten per kilogram of food) is the only treatment available to cure Celiac disease.

At ICAR-CTCRI, gluten free cookies were prepared by replacing wheat flour up to 50% - 60% along with other ingredients like rice flour, tapioca flour, sweet potato flour, taro flour and sorghum flour. The cookies are available in various shapes and sensory quality is acceptable to the consumers.Gluten-free breads were prepared by substituting wheat with 50% sweet potato flour or 30% taro flour with acceptable sensory quality.